In the vast world of engineering and manufacturing, there are countless components and mechanisms that play crucial roles in various applications. One such unsung hero is the O-ring—a small, unassuming ring that has revolutionized sealing solutions across industries. In this article, we will delve into the world of O-rings, exploring their design, applications, and importance in ensuring efficient and reliable sealing.

What is an O-Ring?

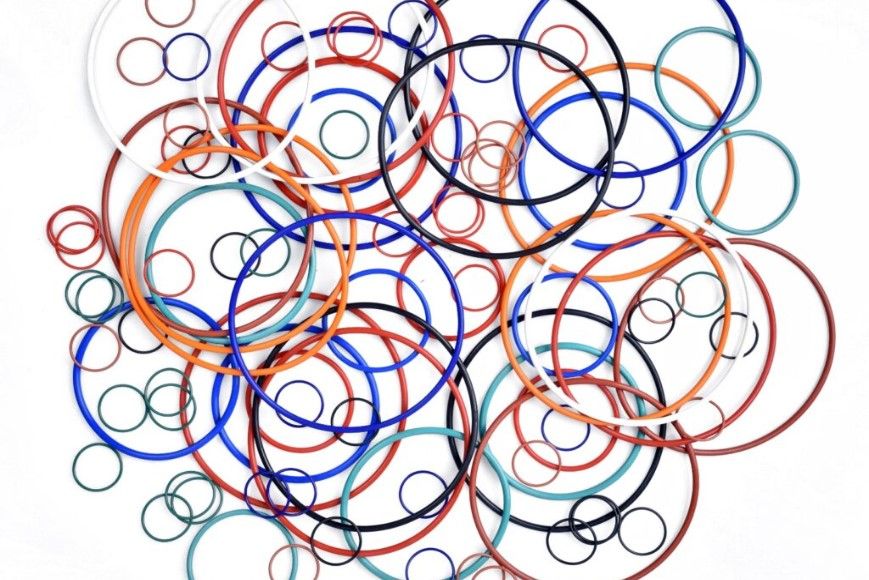

An O-ring is a circular elastomeric ring with a cross-section that resembles the letter “O,” hence the name. Typically made from rubber or other elastomeric materials, O-rings are designed to create a secure seal between two mating surfaces, preventing the escape or entry of fluids or gases. The key to their effectiveness lies in their ability to withstand deformation and maintain a tight seal even under challenging conditions.

Design and Composition

O-rings are available in a wide range of sizes, materials, and designs to suit specific applications. The most common material used for O-rings is nitrile rubber (NBR), known for its excellent resistance to oil, fuel, and other petroleum-based fluids. Other popular materials include silicone, fluorocarbon (Viton®), ethylene propylene diene monomer (EPDM), and polytetrafluoroethylene (PTFE), each offering unique properties suitable for different environments.

The design of an O-ring is crucial for its sealing performance. The cross-section profile can vary, with popular shapes including round, square, and rectangular. The choice of the appropriate cross-section design depends on factors such as pressure, temperature, fluid compatibility, and the specific geometry of the sealing application.

Applications in Diverse Industries

O-rings find applications in a wide range of industries, playing a vital role in ensuring leak-free and reliable sealing. Let’s explore some notable sectors where O-rings are extensively used:

- Aerospace and Aviation: O-rings are employed in aircraft engines, hydraulic systems, and fuel systems, where they must withstand extreme temperatures, pressures, and exposure to fuels and lubricants.

- Automotive: O-rings are found in engines, transmissions, braking systems, and fuel systems, providing effective sealing against oil, coolant, fuel, and hydraulic fluids.

- Manufacturing and Machinery: O-rings are widely used in pumps, valves, cylinders, and hydraulic systems, providing leak-proof seals and preventing contamination.

- Medical and Pharmaceutical: O-rings are utilized in medical devices, fluid handling systems, and drug delivery systems, ensuring sterile environments and preventing fluid leakage.

- Plumbing and Fluid Handling: O-rings are crucial in plumbing fixtures, faucets, valves, and pipe connections, preventing leaks and maintaining efficient fluid flow.

Importance and Benefits

The significance of O-rings lies in their ability to provide reliable and cost-effective sealing solutions. Here are some key benefits:

- Versatility: O-rings can accommodate a wide range of operating conditions, making them suitable for diverse applications in different industries.

- Reliable Sealing: O-rings create a robust seal, preventing leakage of fluids or gases, thereby enhancing safety, efficiency, and product performance.

- Easy Installation and Maintenance: O-rings are simple to install and replace, minimizing downtime and maintenance costs.

- Cost-Effectiveness: O-rings offer a cost-effective sealing solution compared to other sealing methods, such as gaskets or mechanical seals.

O-rings may be small in size, but their impact on various industries cannot be overstated. These versatile sealing components have transformed the way we achieve leak-free connections, ensuring the safe and efficient operation of countless machines and systems. From aerospace to automotive, manufacturing to medical, O-rings continue to play