When it comes to sealing applications, versatility and adaptability are key factors. One such solution that offers immense flexibility is the O-ring cord. O-ring cords are specialized sealing materials that can be custom-cut to create O-rings of various sizes. In this article, we will explore the significance of O-ring cords, their construction, and the advantages they offer in different industries and applications.

Understanding O-Ring Cords

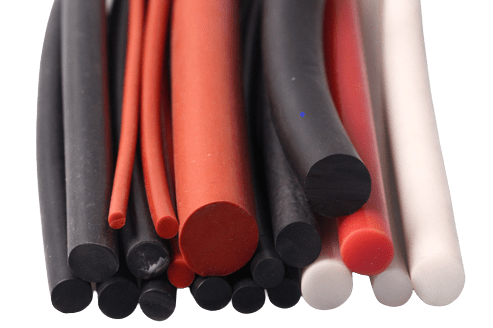

O-ring cords are continuous lengths of elastomeric materials, typically made of materials like nitrile rubber (NBR), fluorocarbon rubber (FKM), silicone rubber (VMQ), or EPDM rubber. These cords are manufactured with precise tolerances and are available in different diameters, allowing for customized sealing solutions. O-ring cords are widely used in various industries, including automotive, aerospace, plumbing, and manufacturing, due to their versatility and sealing capabilities.

Construction and Customization

O-ring cords are made from high-quality elastomeric materials that exhibit excellent resilience, flexibility, and resistance to environmental factors. They are available in a variety of cross-sectional shapes, such as round, square, and rectangular, to accommodate different sealing requirements. The cords can be easily cut to the desired length and joined using adhesive or vulcanization techniques to create customized O-rings.

Advantages of O-Ring Cords

- Flexibility and Customization: O-ring cords offer unparalleled flexibility in creating seals of varying sizes and dimensions. This adaptability makes them suitable for a wide range of applications, from simple sealing tasks to complex machinery. Manufacturers can easily cut the cords to the required length and join them to form O-rings that precisely fit specific equipment or components.

- Cost-Effective Solution: O-ring cords provide a cost-effective alternative to pre-formed O-rings. By purchasing cords in bulk, manufacturers can optimize material usage and reduce inventory costs. The ability to cut and customize the cords as needed minimizes waste and ensures an efficient sealing solution for each application.

- Reliable Sealing Performance: O-ring cords, when properly installed, create a reliable and effective seal. The elastomeric material used in their construction offers excellent resistance to fluids, chemicals, temperature variations, and pressure. This reliability ensures that O-ring cord seals can withstand demanding environments and prevent leakage, contributing to the overall efficiency and performance of the system.

- Versatility in Applications: O-ring cords find applications in various industries due to their versatility. They are used in hydraulic systems, pneumatic systems, pumps, valves, engines, and other mechanical components. The cords can seal fluids, gases, and even vacuum applications, making them suitable for diverse industries such as automotive, manufacturing, pharmaceuticals, and more.

- Easy Installation and Replacement: O-ring cords are simple to install, especially when compared to other sealing solutions. Their flexibility allows for easy positioning and fitting into grooves or gaps. Additionally, when replacement is necessary, O-ring cords can be quickly cut and installed, reducing downtime and maintenance costs.

Conclusion

O-ring cords offer a versatile and customizable sealing solution for a wide range of applications. Their flexibility, cost-effectiveness, reliable sealing performance, and ease of installation make them highly advantageous for industries seeking efficient and adaptable sealing solutions. By utilizing O-ring cords, manufacturers can achieve reliable and effective seals that contribute to enhanced system performance, reduced downtime, and improved overall productivity. Whether in automotive, aerospace, plumbing, or manufacturing, O-ring cords are a reliable choice for sealing needs in diverse industries.